PHANTOM : Creating the future from waste

Apparatus to detoxify and treat various types of organic waste

- Decompose waste previously impossible or difficult to decompose

- Only harmless residue is produced through PHANTOM

- Close to no carbon dioxide produced

Product characteristics

PHANTOM produces sub-critical water with saturated steam at high temperature and high pressure, which hydrolyses organic waste and lowers molecular weight.

Since PHANTOM does not burn, it prevents the generation of dioxins and suppresses the generation of carbon dioxide.

PHANTOM has a simple structure, and the maintenance process is the same as for pressure tank packing replacement and boilers, keeping the cost of regular inspections low.

PHANTOM features

Cost efficiency

Introducing PHANTOM will make it possible to reduce the otherwise high cost of industrial waste disposal,leading to improved profitability.

3 tonnes of waste decomposed within 45 minutes

With overwhelmingly high processing power compared to other similar products, it is heightens the possibility investment recovery and improves business efficiency.

Break down various types of waste

Proven success in decomposing a wide variety of industrial waste. It is also possible to decompose multiple types of industrial waste at the same time.

Water treatment ensures safety

Safely treats various industrial wastes without generating carbon dioxide or dioxins.

Possible reuse of residues

In addition to treating waste, it is possible to reuse the residue for fertilizer, feed or fuel to improve profitability.

Easy operation for any user

The device is automatically operated with touch buttons, making it very easy to use.The operation method changes depending on the input.

How PHANTOM works

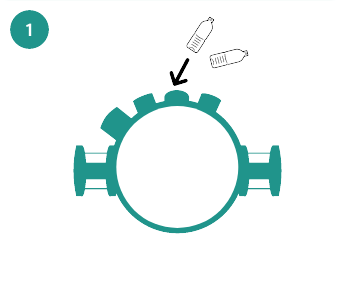

Put in plastic bottles(waste) and water

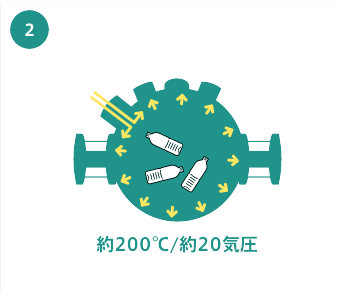

Insert vapor to attain a subcritical state at approx. 200℃, 20 atmospheric pressure

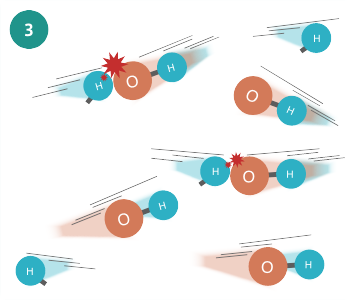

Water turns into H⁺ and OH⁻ in a subcritical state,where they fly around at high speed and collide to generate plasma

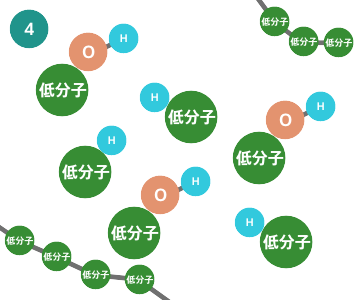

Hydrolysis occurs, where H⁺ and OH⁻ flying around at high speed decompose high molecular into low molecular

Waste is safely processed with no carbon dioxide or dioxin produced. The residues are sterilized and detoxified.

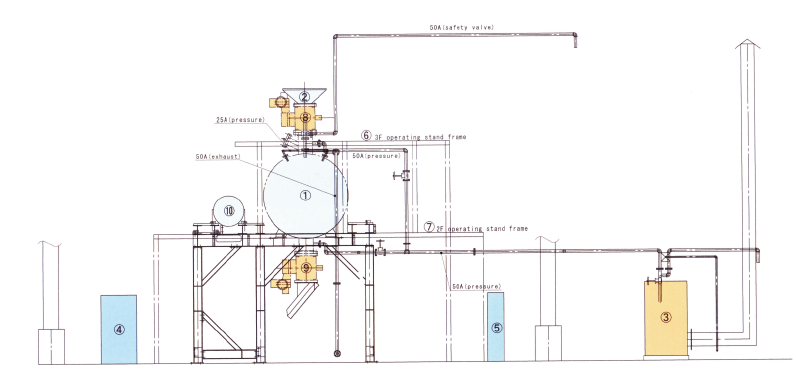

PHANTOM Installation example

- Electrolytic high pressure tank

- Hopper700*700*300

- Boiler1200*2400*2000

- Deodorant/silencer10000*2000H

- Operation board1000*1800

- 3F Stand

- 2F Stand

- IN Ball pipe

- OUT Ball pipe

- Drive monitor

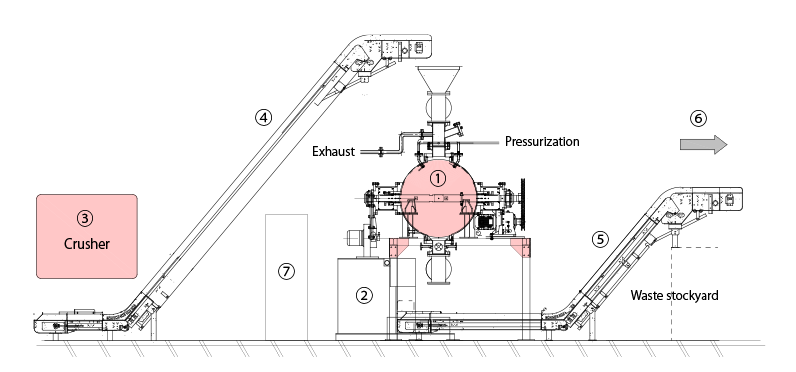

Installation of PHANTOM recycling plants

- Electrolysis/high pressure processing machine

- Boiler

- Crusher

- Input conveyor

- Discharge conveyor

- Pellets, power generation, heat treatment (volume reduction) and other production line

- Operation board

③④⑤⑥are optional

What PHANTOM can treat

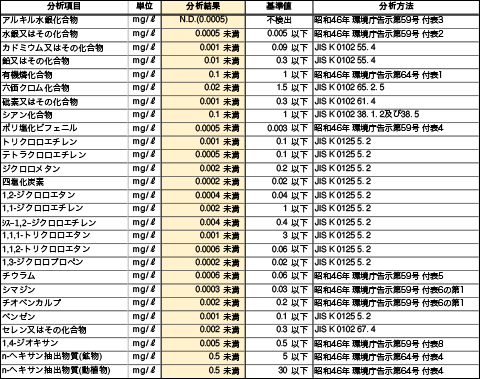

PHANTOM test results using plastic bottles

- Input

-

500 plastic bottles for cold beverages (with caps and labels)

Water (60L of drinkable groundwater) - Wastewater after treatment

-

20L water content (milky in color)

- Constituents in water

-

Refer to the result of analysis (harmless)

- Precipitates

-

Approx. 10% of water-soluble components

※Turning into powder after being strained and dried, the amount will be reduced to approximately 1 percent.

Toyo Environmental Laboratory, K.K.

The environmental burdens of discharging the processed water after treatment into sewers need to be analyzed separately, as each industry has its own treatment method and standard.

Solvable Challenges

We are faced with challenges with no immediate solution in sight such as plastic bottles and plastic waste in the ocean, livestock waste, pollutants, and final disposal site.

As one of the answers to these waste disposal issues, we developed an apparatus that makes plastic waste harmless and drainable in just 35 minutes through high pressure plasma electrolysis, which would become one of the solutions to the challenges of waste disposal. In addition, it detoxifies a variety of waste, including livestock waste, kitchen refuse, food waste, and fishery waste, and turn them into fertilizers. It would also help to tackle a variety of social issues.

Lineup

| 3㎥ (3t) | 2㎥ (2t) | 1㎥ (1t) | 0.5㎥ (0.5t) | |

|---|---|---|---|---|

| Basic machine weight | 12ton | 10ton | 4ton | 3ton |

| Size of the pressure vessel (diameter) | 190cm | 160cm | 110cm | 80cm |

| Size of the input port (diameter) | 30cm | 30cm | 20cm | 20cm |

| Maximum possible load | 3ton | 2ton | 1ton | 0.5ton |

| Anticipated amount of discharge | 1.8ton | 1.2ton | 0.6ton | 0.3ton |

| Actual treatment time | 45min. | 45min. | 30min. | 30min. |

| Estimated treatment utility cost | 3,000yen | 3,000yen | 3,000yen | 3,000yen |

- Basic machine/Pressure vessel, mixer, motor, ball valve, control panel, piping, frame, lift for products

- Boiler (30 atmospheric pressure/Steam generation quantity@1 ton/H)

- Tank, piping etc., surface treatment cost

- Charges:Design, gauges and instruments, cost of on-site assembly operation

- Land, building, belt conveyer

- Resizing of the valves for custom specification,charges involved in changing the frame

From pricing to delivery

Please contact us for price quotations.

Free of charge

Time frame:

About 4weeks

Defining production requirements

- The amount of organic waste your company treats in a day

- The content of the waste

- The current waste sorting method

- Whether or not a building could be set up

- The condition of the ground, etc.

Deposit:50%

Time frame:

About 3weeks

Contracts/

Arrangements

- Getting an approval for the proposed design

- Executing an agreement

- Setting up a building

- Checking the condition of the ground

The remainder of the payment:30%

Time frame:

About 6months

Manufacturing/

Test operation

- On-site inspection

- Applying to Labour Standards Inspection Office for manufacturing approval

First class pressure vessel - Manufacturing (5 to 6months)

- Test operation

- Witnessed demonstration/Approval

The remainder of the payment:20%

Time frame:

About 2weeks

Making a contract on operation and maintenance

- On-site installation work

- Test operation

- Screening by the Labor Standards Inspection Office

- Delivery→Completion

*The operator training will be done using our 1m3 equipment during the manufacturing period.